Welcome to the official website of Shandong Zhuoli Xinyuan Intelligent Technology Co., Ltd.

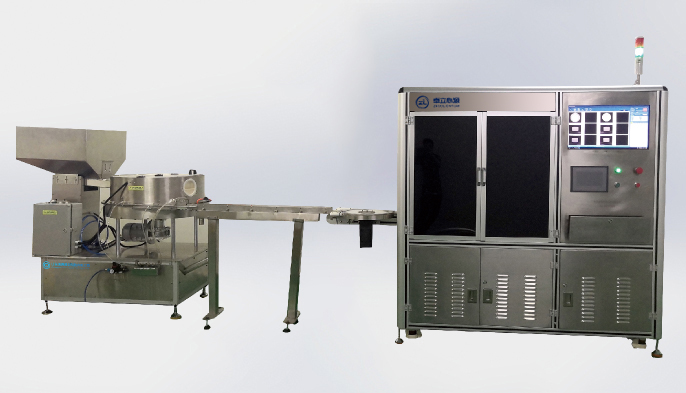

The fully automatic high-speed plastic cover detection machine adopts feeding method of waterfall lifting feeding or centrifugal feeding, and adopts visual detection technology to carry out 360-degree detection on the front, back and side of the plastic cover. It is suitable for the appearance detection of various sizes of plastic cover, with data statistics function, and can be divided into the designated collection container.

·360 degree blind spot detection of the cover in all directions.

·Rapid modeling and variety management for different products, sorting of mixed colors.

·Real time storage of detection data, supporting data export.

·The equipment is easy to operate, stable to operate, and easy to maintain.

| Applicable products | Plastic covers (regular covers for pharmaceuticals, beverages, cosmetics, etc.) | ||

| Defect detection | Gasket defects, backpads, gaskets dirty, black spots, missing pads; External side size gap, side dirt, black spots, scratches; Dirty back, black spots Defective gasket, reverse gasket, dirty gasket, black spots, missing gasket; Large and small notches on the outer side, dirt, black spots, and scratches on the side; Dirty back, black spots. | ||

| Detection speed | 400-600 pcs/min (Depending on the size of the diameter and whether the direction needs to be adjusted) | ||

| Visual imaging system | CMOS/CCD Industrial camera, high-resolution lens | ||

| Dimensional appearance | 2400(L)*800(W)*1700(H)mm | Detection accuracy | 0.05mm |

| Rated power | 2.3KW | Weight | 280KG |

| Powder supply | AC380V,50/60Hz | Pressure | 0.4-0.7mPa |

鲁公网安备 37021302001142号

鲁公网安备 37021302001142号