Welcome to the official website of Shandong Zhuoli Xinyuan Intelligent Technology Co., Ltd.

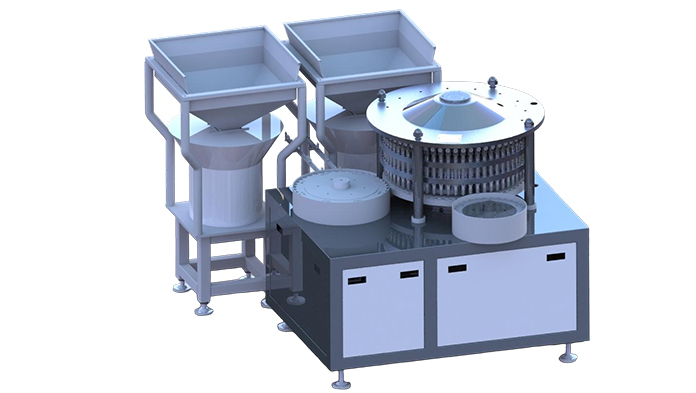

Full-automatic cushion (plug) machine is a kind of automated equipment for inserting the cushion (race) into the lid in the industrial production kind, which is widely used in the scenarios requiring high-precision assembly and quality control in the industries of pharmaceuticals, alcoholic beverages, chemicals and so on. The equipment in the complete realization of loading, material handling and insertion of plugs (pads) process automation at the same time, but also can be connected to the visual inspection system, after the production of products directly for defect detection, to achieve the production, quality control, packaging, the whole process of automation. At the same time, the equipment is equipped with an intelligent diagnostic system, which can monitor the running status of the equipment in real time and realize the precise positioning of the problem when the equipment fails, greatly improving the intelligent level of enterprise production.

High applicability

-Widely used in intelligent production in pharmaceutical, liquor, chemical

and other industries;.

-High compatibility and versatility for different models of the same

product.

Precise and high efficiency

-Equipment adopts 60 rods rivet head structure, production efficiency up to

55000 pcs/hour, high production efficiency, finished product qualified rate up

to 99.2%~99.4%; -Equipment adopts 60 rods rivet head structure, production

efficiency up to 55000 pcs/hour, high production efficiency, finished product

qualified rate up to 99.2%~99.4

-Visual inspection speed up to 3200pcs/min, inspection accuracy up to

0.02mm.

Stable and high quality

-The transmission structure adopts spiral bevel gears with long life, low

noise and high precision of biting.

-No lubricating oil, no heating pollution.

-Plugs (pads) are not wrinkled, not beveled edges, and the leveling height

is consistent.

Intelligent manufacturing

-The back-end can be paired with self-developed AI-based intelligent visual

inspection system, which can independently model and intelligently identify

product defects without excessive human intervention; -The equipment is paired

with an intelligent diagnostic system, which can be used to identify product

defects without excessive human intervention.

-Equipment with intelligent diagnostic system, real-time monitoring of

equipment operating status and fault information for independent localization;

-Data management module of the equipment background management system.

-The data management module of the background management system of the

equipment can collect, store and summarize the data generated by the operation

of the equipment and support historical data query, providing basic data for the

establishment of digital and intelligent factories.

The data management module of the equipment background management system

can collect, store and summarize the data generated by the equipment operation

and support historical data query, providing basic data support for enterprises

to establish digital and intelligent factories.

| Product Name | Full - Automatic Gasket (Plug) Inserting Machine |

Product Model | ZL - JDS - 2501 |

Body Material | Stainless Steel |

Rated Voltage | 380V |

Rated Power | 11Kw |

Yield Rate | 99.2% - 99.4% |

Production Efficiency | 55,000 pcs/hour |

Equipment Dimensions | 500mm1140mm1400mm |

| Equipment Weight | 1200kg |

Number of Gasket Pressing Heads | 60 heads |

鲁公网安备 37021302001142号

鲁公网安备 37021302001142号