Welcome to the official website of Shandong Zhuoli Xinyuan Intelligent Technology Co., Ltd.

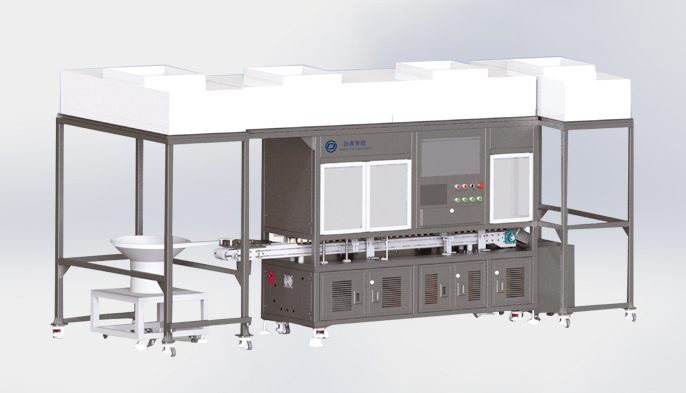

The fully automatic polycarbonate infusion plug testing machine is divided into four units: feeding unit, detection unit, defective product removal unit, and discharge unit. The testing machine adopts a vibrating feeding method to detect the top, transparent plastic area on the upper side, and aluminum plastic cover part on the lower side of the polycarbonate infusion plug. It can detect defects such as injection black spots, injection bubbles, silver lines, interface shortage, aluminum cover gap, incomplete sealing, aluminum cover wrinkling (severe), plastic sheet gap, yellowing, etc.

·Real-time storage of detection data, detection results, real-time images, and dynamic display of running status on the display.

·Modular design of the equipment, simple interface operation, stable system, simple maintenance, convenient cleaning, and compliance with GMP standards. The overall equipment needs to meet the standards of a 100000 level purification workshop.

·Defective products are automatically accurately located and eliminated at a high speed, and qualified products are automatically counted and distributed to designated collection containers.

| Test Specification | Multi specification polycarbonate infusion plugs | ||

| Defect detection | Injection molding black spots, injection bubbles, silver threads, missing material cover gaps at interfaces, incomplete sealing, wrinkling of aluminum covers, yellowing of plastic sheet gaps. | ||

| Detection speed | 100-250/min | ||

| Visual imaging system | CMOS/CCD Industrial camera, high-resolution lens | ||

| Detection accuracy | 0.01mm | Weight | 300kg |

| Dimensional appearance | 1860(L)*1360(W)*2150(H)mm | Pressure | 0.45-0.8MPa |

| Powder supply | 380V,50/60HZ Three-phase AC | Rated Power | 1.45KW |

鲁公网安备 37021302001142号

鲁公网安备 37021302001142号